THE STORY OF A FAMILY AND THEIR PASSION

The Seppeler family is now running the family business in the 4th generation. It was founded with courage, creativity and passion – and these emotions still ring true today and for the business of the future.

MAN AND TECHNOLOGY

The interaction between man and technology has been a point of focus for more than a hundred years. However, we do not see the old world of tradition and the modern age of globalism at variance with each another. We confront the changing market landscape and conditions with a large helping of adaptability and indeed with delight in making new decisions in a new world.

- Unterstützung in Produktionsprozessen

- Verpacken der Ware

- operative Verantwortung für die Anlage & Fachliche Führung eines kleinen Teams

- Einrichtung & Inbetriebnahme der Anlage

- Gute Deutschkenntnisse erforderlich

- Versorgung der Arbeitsplätze mit Material

- Be- und Entladen der LKWs

- Staplerschein notwendig

- Durchführung von Produktprüfungen

- Kontrolle der Personal- und Betriebshygiene und Überwachung der Metalldetektoren

- Bereitschaft in Wechselschicht zu arbeiten

- Unterstützung in Produktionsprozessen

- Verpacken der Ware

- operative Verantwortung für die Anlage & Fachliche Führung eines kleinen Teams

- Einrichtung & Inbetriebnahme der Anlage

- Gute Deutschkenntnisse erforderlich

- Versorgung der Arbeitsplätze mit Material

- Be- und Entladen der LKWs

- Staplerschein notwendig

- Durchführung von Produktprüfungen

- Kontrolle der Personal- und Betriebshygiene und Überwachung der Metalldetektoren

- Bereitschaft in Wechselschicht zu arbeiten

CHANGE, INNOVATION & RESEARCH

"Come what may, we will always have to be that little bit better than we were yesterday, better than our competitors and better than is expected of us."

Dr Klaus Seppeler

This was Dr Klaus Seppeler’s way of describing his vision of the company’s continuing innovation. In retrospect, this mindset mirrors the entire history of the Seppeler Group. Particularly when it comes to products and technologies, where, from the very beginning, there has always been a great deal of openness and a forward-looking perception of change, innovation and research.

HISTORY IN PICTURES

- Unterstützung in Produktionsprozessen

- Verpacken der Ware

- operative Verantwortung für die Anlage & Fachliche Führung eines kleinen Teams

- Einrichtung & Inbetriebnahme der Anlage

- Gute Deutschkenntnisse erforderlich

- Versorgung der Arbeitsplätze mit Material

- Be- und Entladen der LKWs

- Staplerschein notwendig

- Durchführung von Produktprüfungen

- Kontrolle der Personal- und Betriebshygiene und Überwachung der Metalldetektoren

- Bereitschaft in Wechselschicht zu arbeiten

Come and join us on a journey through time and learn more about the background of the Seppeler Group and the Rietbergwerke, the very beginnings of today’s company, whose history spans more than 100 years.

Please rotate the device to portrait format

The journey through time runs chronologically from left to right.

Please use the

mouse

or

„Drag & Drop“

for navigation.

To navigate, just

swipe to the left.

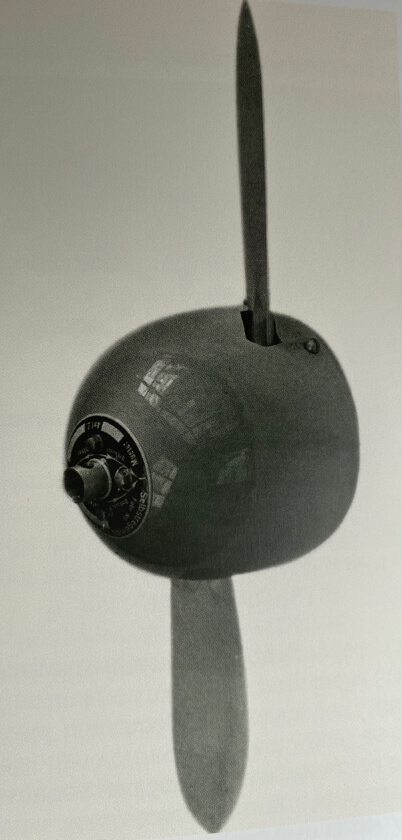

1917

Variable pitch propeller

Dipl.-Ing. Eduard Seppeler founds a construction office for the flight industry in Berlin. He develops and produces aircraft engine test benches, variable pitch propellers and refuelling systems for the aviation industry.

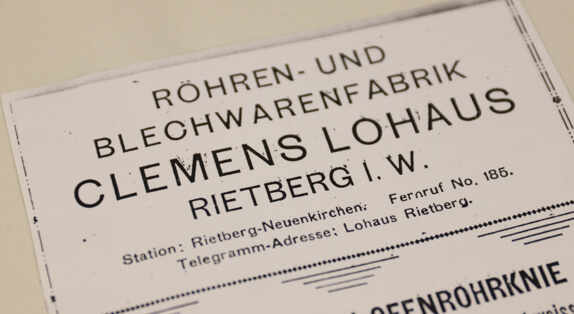

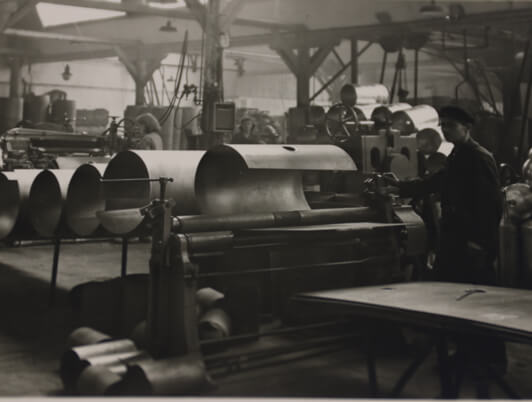

1919

The founding

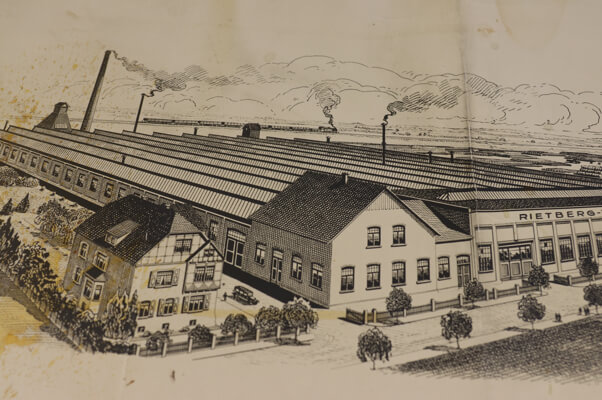

Businessman Clemens Lohaus establishes a factory for tubes and tin products in Rietberg in 1919. The first galvanizing plant is built in 1922 for the galvanizing of own products. The first wrought-iron barrels are made the following year.

1925

Rietbergwerke

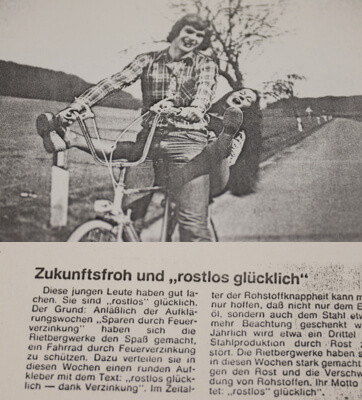

The Röhren- und Blechwarenfabrik is renamed Rietbergwerke Aktiengesellschaft. The name "Rietbergwerke" is maintained to this day at the headquarters in Rietberg, the core of today's Seppeler Group.

1929

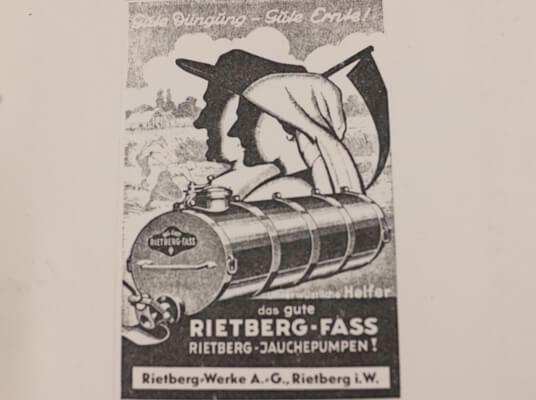

Agriculture equipment

Agriculture equipment is now added to the range. The increasing mechanisation within the agriculture industry calls out for galvanized manure containers and feed cookers.

1936

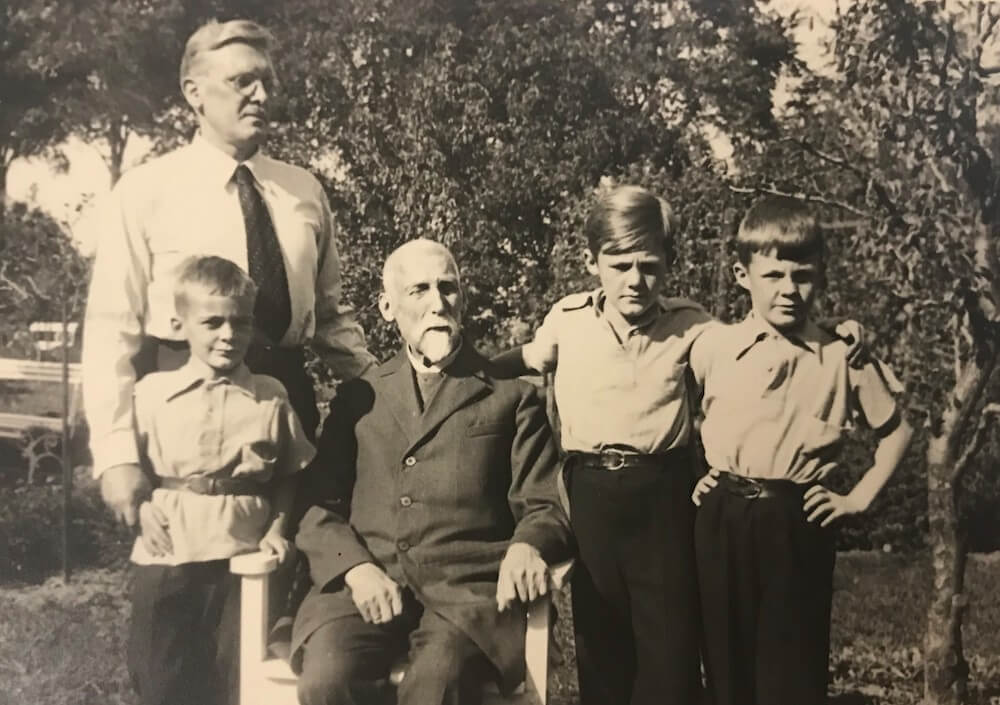

The Seppeler family

The Seppeler family, who have lived in Rietberg, East Westphalia, since the 15th century, establish their entrepreneurial commitment in 1936 with the takeover of the majority of shares in the Rietbergwerke AG through the Seppeler Foundation for Aviation and Automotive, based in Berlin.

At the same time, the production of Seppeler test benches and refuelling systems are relocated to Rietberg-Neuenkirchen.

Dipl.-Ing. Eduard Seppeler (here with his father Prof. Georg Seppeler and his sons (from left to right) Wolfgang, Jürgen and Klaus) is the owner of the foundation and is considered a pioneer and ingenious inventor in the field of aviation and automotive.

The product diversity within the course of the following years are enormous. Allow former employees to tell you about this.

This video is only available in German.

View Video1949

Galvanized small tanks

Rietbergwerke, in cooperation with the petroleum industry, develop galvanized small tanks. They become known as "Rietberg tanks" not only in the agriculture area.

1950

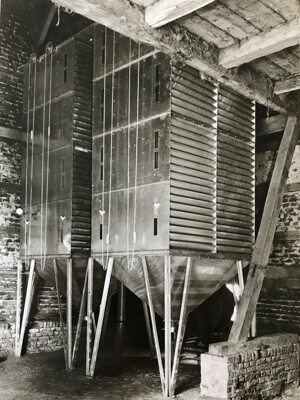

Dryers

The 1950s are marked by upheavals in agriculture. Through the use of fertilisers, production could be increased enormously. At the same time, the use of machines make work easier.

The Rietberwerke contribute its part to the food security with their manufacturing of equipment and facilities for drying and storing grain. The new tower dryer is developed in 1955. It turns out to be the best-selling dryer and one of the most successful products. The Rietbergwerke become the market leader in airing and drying technology.

1956

Heating-Oil Battery Tanks

The production of heating-oil battery tanks come to the fore. Many households need the tanks to convert heating systems to oil as fuel. The demand is enormous.

With the manufacture of double-walled containers and special heating-oil battery tanks, the company starts developing products that are committed to environmental protection.

1959

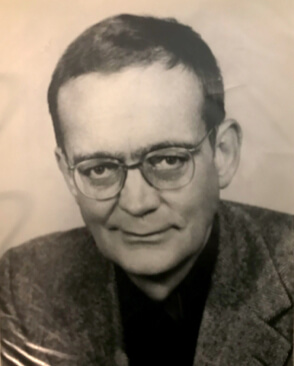

Dr. Klaus Seppeler

After joining the Rietbergwerke in 1953, Dr. Klaus Seppeler becomes sole managing director in 1959. He takes numerous measures to modernise production processes and sales, in this way laying the foundations for the dynamic growth of the company in the 1960s and early 1970s.

As co-founder of the Association for Hot Dip Galvanizing, his aim is to make the process of hot dip galvanizing and its benefits better known to the public.

Dr. Klaus Seppeler plays a decisive role in determining the fate of the company for more than 50 years.

Kai Seppeler talks about his father

Dr. Klaus Seppeler.

This video is only available in German.

1960

Advertising

The creating of an independent marketing department begins as early as 1960. An own logo and the first marketing strategies are developed here.

Within a very short time, the company is given a modern and at the same time sophisticated public image with aesthetic components, as well as unusual advertising slogans and brand names.

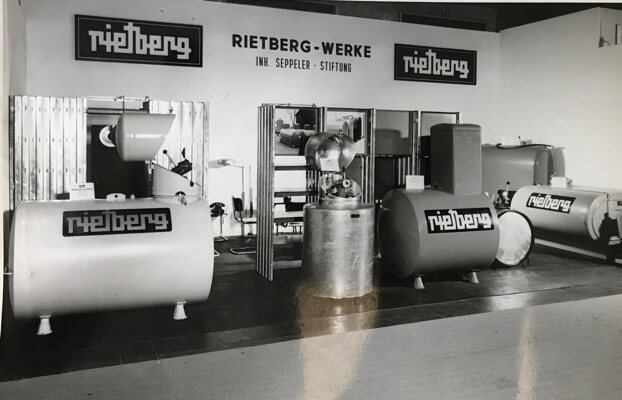

Exhibitions

To show presence and performance, and getting into conversation with the customer. Elaborately designed exhibition stands become meeting points and at the same time promote a modern appearance.

1965

Europe’s most modern plant

Hot dip galvanizing becomes increasingly significant as "the most effective corrosion protection for steel". The Rietbergwerke builds the most state-of-the-art hot dip galvanizing plant in Europe with a bath dimension of 14.20 m length. Commission galvanizing now accounts for almost 1/3 of the total turnover. With the construction of this galvanizing plant, the orientation of the Rietbergwerke changes fundamentally. Hot dip galvanizing becomes the company's core business.

1974

Wolfgang Seppeler

Wolfgang Seppeler, the younger brother of Dr. Klaus Seppeler, is not only responsible for internal organisation and modernisation, as well as product design in the company, he also directs the project mentioned below. With the introduction of a product group organisation, the company has achieved a quantum leap in terms of the development and mobilisation of personal responsibility, product identification, flexibility and thus ultimately also the profitability.

Industrial history is shown in the change in jobs. Whereby the theme "People and Work" has always played a vital role at the Rietbergwerke. The production organisation and the project "Humanisation of Working Life (HdA)", which was implemented in cooperation with the Technical University of Berlin, were mainly supervised by Wolfgang Seppeler.

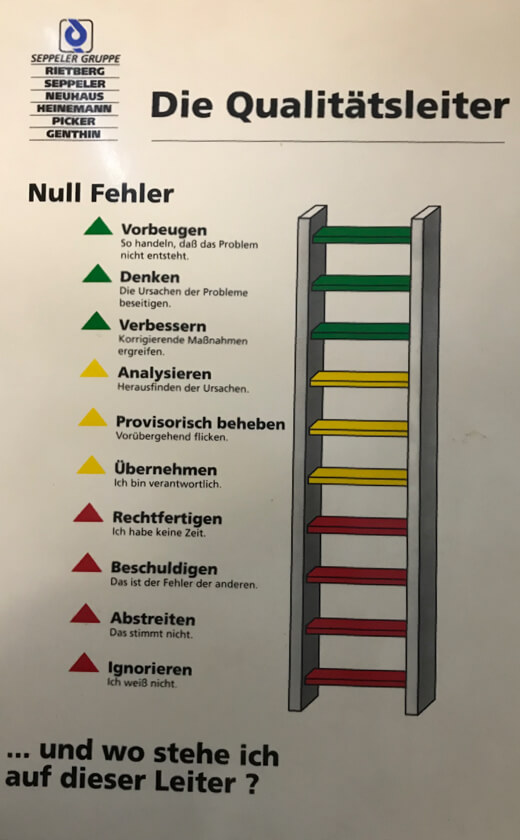

Promote and encourage

Dispensing of strict management, detailed instructions and close control. In its place, personal initiative and personal responsibility. Based on the motto "promote and encourage", the determination to solve problems independently is encouraged in the Rietbergwerke. A good working climate between colleagues, also outside of the workplace, plays an important role.

1974

The Seppeler Group begins to grow

The strategic growth of the Seppeler Group begins with the acquisition of the Helling & Neuhaus company in Gütersloh. In addition to a second galvanizing plant, the company acquires a new production division for the first time: steel gratings.

The development of new regional markets and the expansion of the product range continue to this day. The Seppeler Group now has 15 locations. Click here for an overview of the Seppeler Group’s expansion.

The Expansion of the Seppeler Group

1983

Kai Seppeler

Kai Seppeler joins the Seppeler Group. As managing director, he continues to drive the market development and expansion of the company. The equally market and future-oriented alignment of the Seppeler Group is appropriately expressed in its mission statement: "Seppeler – we make it work". It is a commitment, in all our areas of business as productive service providers, to give each of our customers an individual and special service. "We make it work" is a message both externally and internally and thus the demand on our own work.

„Sustainability and trust are essential foundations of our corporate culture, as it has been shaped by the Seppeler family over generations. As a family, it is our task to secure the future existence of the Seppeler Group companies with their jobs and to create the framework for sustained success.“

Kai Seppeler,

Chairman of the Supervisory Board

1984

Special containers for environmental protection

The first special container for environmental protection is produced in the business area container technology: the waste-oil storage tank No.950. In 1987, the waste-oil storage tank designed by industrial designer Karl Heinz Keunecke is awarded the “North Rhine-Westphalia’s State Prize for Design and Innovation”.

1987

Duplex-System

The surface protection for hot dip galvanizing is extended by the Duplex-System. The additional coating increases the durability of the hot dip galvanizing and also enables an attractive appearance using the full range of colour design.

The coating of galvanized parts and other materials becomes increasingly important in the following years. The Seppeler Group sets up its own powder and wet coating facilities at many locations in order to be able to offer the customer optimal quality from a single source. Thus, the foundation for the fourth business division of the Seppeler Group is laid.

1991

"The Strong Connection"

The Seppeler Group presents itself to the outside with a new logo and the slogan "The strong connection". Under a central strategic management, the companies continue to operate as legally independent entities. The productive connection between the companies and their staff is expressed in the newly developed logo "productive service providers".

This connection is symbolically illustrated in a three-dimensional sculpture by Prof. Fiebig, which still symbolizes the innovative dynamics of the group today.

1997

Entry into the Polish market

In Chrzanów, near Krakow, the first overseas plant for the Seppeler Group, the Ocynkownia Śląsk Sp. z.o.o., is built. The plant is specially designed for particularly large and heavy steel structures. In 2007 the construction of the Polish branch in Kluczbork follows.

In 2013 and 2017, the Seppeler Group acquires additional galvanizing plants in Czestochowa and Swidnica, thereby further expanding its market position in southern Poland and consequently adding a high-temperature plant to its product range.

In 2002 the Seppeler Group acquires a majority sharehold of the Polish grating manufacturer Kraty Mostostal Krakow.

2003

Dr. Klaus Seppeler Foundation

The company-related Dr. Klaus Seppeler Foundation is established in the legal form of a family foundation. The Foundation’s mission is to secure and promote all fundamental decisions in the sense of the company and family’s philosophy in a sustainable and long-term manner.

The research and development of scientific projects and innovations within the entire Seppeler Group is encouraged and supported.

2004

Founding of the Seppeler Holding

The Seppeler Group is reorganised in 2004. The Seppeler Holding, which emerged from the Rietbergwerke, and the Dr. Klaus Seppeler Foundation, which was established the previous year, form the cornerstones of a modern corporate structure. The corporate culture developed over decades and the close ties to the Seppeler family represent a successful development of the Group’s independently operating companies.

2008

Local involvement

The Seppeler Group attaches great importance to local involvement. For example, a bridge was donated to the city of Rietberg for their National Horticultural Show.

2018

Nina Seppeler

Nina Seppeler has been with the company since 2004. In the positon of Managing Director, she takes over the coordination and control of the Polish plants in 2018. In 2020 she is appointed to the management of Seppeler-Rietberg GmbH. After Kai Seppeler's move to the supervisory board in 2018, the Seppeler family continues to be represented by a member on the executive board. Nina Seppeler attaches particular importance to the continuation of the family and corporate culture. Her motto "Burn for what you do and do what you burn for. Then you will succeed" is a claim and incentive for her in her management position and in the fulfilment of her tasks.

2008

Local involvement

The Seppeler Group attaches great importance to local involvement. For example, a bridge was donated to the city of Rietberg for their National Horticultural Show.

2019

100-year anniversary

The Seppeler Group can proudly look back on a history of 100 years. The celebration of the Rietbergwerke’s 100th anniversary is celebrated with many guests who have been associated with the company for many years.

2020

EXPANDING THE COATING SECTOR

The Seppeler Group expands its extensive range of coating services with the new powder coating facility at Helling & Neuhaus in Gütersloh. Black steel, hot dip galvanized or Sendzimir galvanized steel, as well as aluminium can be refined by means of powder coating in accordance with the stringent quality specifications.

Thanks to the diverse colour design, components can be individually customised - an increasing trend in metal construction: more and more hot dip galvanized railings, balconies, fences and gates are being enhanced and accentuated in this way.

Special attention was given to a future-proof and environmentally friendly pre-treatment technology during the planning of the plant.

2021

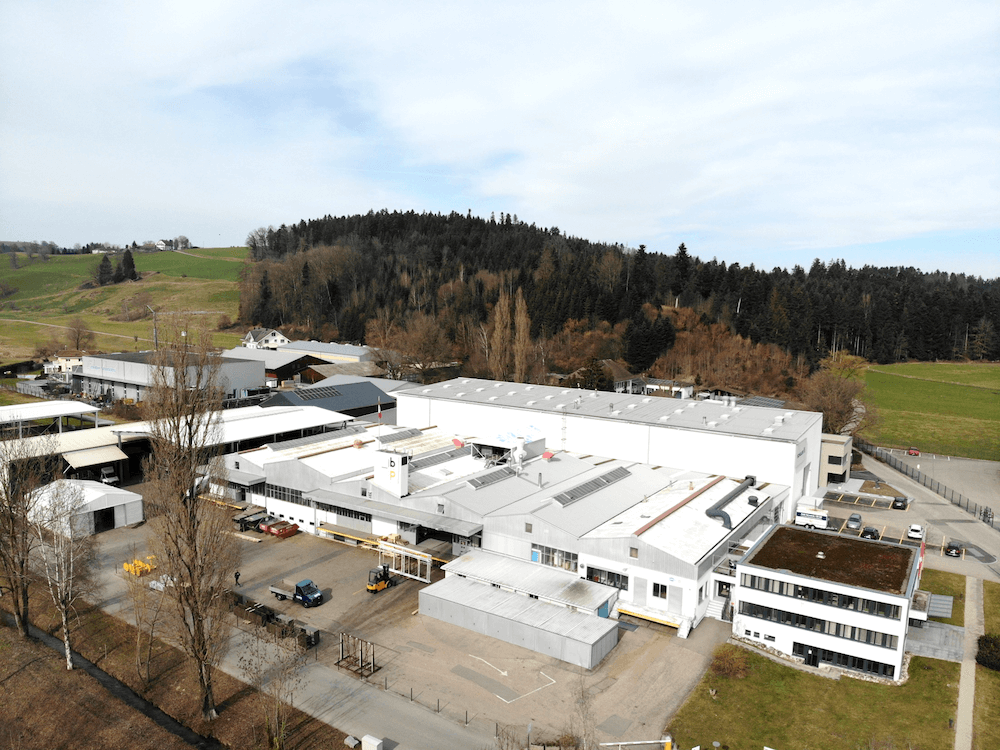

ENTERING THE SWISS MARKET

The acquisition of the Swiss company SDL AG puts the Seppeler Group on course for further growth within Europe. SDL AG has established itself in recent years as a leading provider of surface coating and corrosion protection on the Swiss market and is a genuine traditional company. This success story will continue with the appropriate investments and modernisations.

2022

NEW ESTABLISHMENT OF

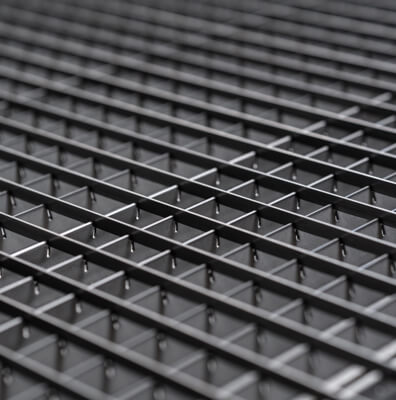

SEPPELER GITTERROSTE GMBH & CO KG.

To be able to operate on the market in an even more customised and target-oriented manner, the grating division was spun off at the start of 2022 from Helling & Neuhaus GmbH & Co. KG and transferred to Seppeler Gitterroste GmbH & Co. KG. As a result, "Seppeler Gitterroste" can present itself as a grating specialised company with a clear brand positioning and a holistic, focused and modern market presence.

In combination with the new company logo and the relaunch of the new website, a harmonious and group-wide uniform external presentation is now in place.

The Seppeler family brand is once again strengthened and illustrates the synergies and the corporate group from which our customers and partners benefit.

2022

The New Corporate Identity

The unified naming of the individual companies under the umbrella of the Seppeler Group is a decisive cornerstone in the company's brand relaunch in 2022. In the course of the year, all German and Polish locations have incorporated the Seppeler name into their respective company names.

Outlook with vision

"Our management will always continue focusing on the interaction between people and technology. By investing in high-performance and environmentally efficient technology and by actively exploiting the opportunities that arise in the market today and tomorrow, we are creating the foundation for our sustainable competitiveness.

We will continue to focus on our customers' needs and requirements in the field of hot dip galvanizing, coating, container technology and gratings. In doing so, we act in the spirit of a family business in the long-term and sustainably, so that we can continue to say: Seppeler – we make it work".

From left to right: Thomas Weise, Kai Seppeler, Nina Seppeler, Stefan Neese

- Unterstützung in Produktionsprozessen

- Verpacken der Ware

- operative Verantwortung für die Anlage & Fachliche Führung eines kleinen Teams

- Einrichtung & Inbetriebnahme der Anlage

- Gute Deutschkenntnisse erforderlich

- Versorgung der Arbeitsplätze mit Material

- Be- und Entladen der LKWs

- Staplerschein notwendig

- Durchführung von Produktprüfungen

- Kontrolle der Personal- und Betriebshygiene und Überwachung der Metalldetektoren

- Bereitschaft in Wechselschicht zu arbeiten

- Unterstützung in Produktionsprozessen

- Verpacken der Ware

- operative Verantwortung für die Anlage & Fachliche Führung eines kleinen Teams

- Einrichtung & Inbetriebnahme der Anlage

- Gute Deutschkenntnisse erforderlich

- Versorgung der Arbeitsplätze mit Material

- Be- und Entladen der LKWs

- Staplerschein notwendig

- Durchführung von Produktprüfungen

- Kontrolle der Personal- und Betriebshygiene und Überwachung der Metalldetektoren

- Bereitschaft in Wechselschicht zu arbeiten

The Expansion of the Seppeler Group

The purchase of the company known as Helling & Neuhaus in 1974 kickstarted the opening up of new markets and the extending of the product range.

Here you can find an overview of corporate expansion.